Productivity

Productivity of machines and worker efficiency in production is achieved with the introduction of production workstations.

Rejects

Achieved by comparing the units that have gone through the production process and those that have been delivered to the warehouse.

Punctual delivery

The delivery accuracy is derived by comparing the realization of the delivery with the dates and items from the customer's order.

Complaints

Complete traceability of complaints. It is possible to trace the flow from delivery to the work order.

WHY PAUK

Knowledge, experience...

The combination of rich working experience in the industry and expertise in the development of systems based on new technologies has resulted in a powerful production management system that covers key aspects of the operational efficiency of processes taking place in production on which every manufacturer depends. In real time, via email or SMS, the system informs employees about the state of production, the execution of work orders and alarm conditions - malfunctions or excessive deviations in energy consumption by machines, production lines, production sites, etc. Measurable results and our easy-to-use system make our system applicable in small companies with only ten employees as well.

“Production sites are places where money is made but also lost.”

The flow of information in real time enables proactive action and the solution of potential problems before the problems emerge.

With the help of PAUK software, our goal is to discover places where money is lost by monitoring production in real time, that is, to increase productivity, reduce production costs and increase competitiveness.

NECESSARY INPUTS

IMPLEMENTATION

DATA PROTECTION

Top attention to the security and protection of your data.

We pay particular attention to the security and protection of your data from manipulation, loss, destruction, access by unauthorized persons or unauthorized disclosure.

PAUK is accessed via standard web browsers from a computer, tablet or mobile device with authorization assigned by a password/RFID card that defines the work authorizations of each employee in the system.

MODULES

MACHINE MONITORING

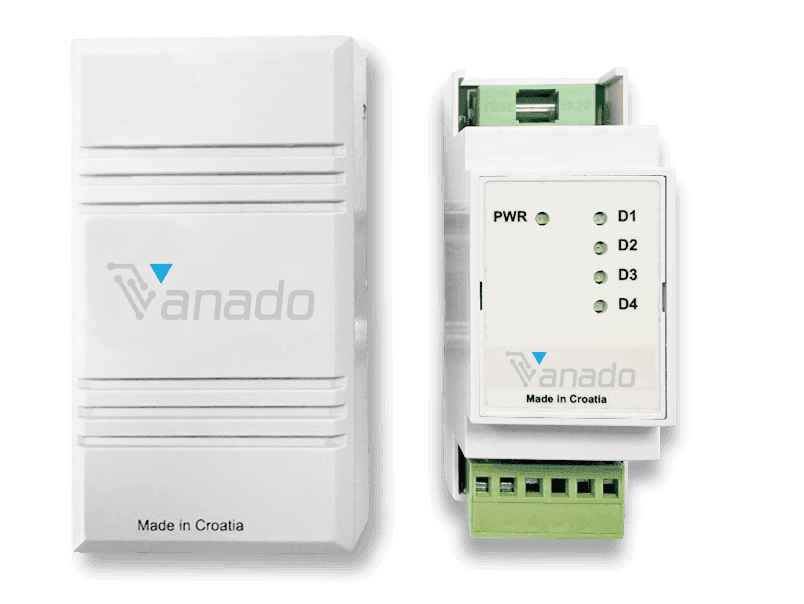

Own R&D

We have developed devices for machine operation monitoring in real time.

The main features of the devices are that they can connect wirelessly or wired via a cable. The devices can pull data directly from the PLC or a sensor that can be placed at the desired location on the machine.

The advantage of these devices is that they can be installed on the machine regardless of the production date. The most common data we collect are the following: whether the machine is working, the number of produced pieces, and the speed of operation.

Projekt je sufinancirala Europska unija iz Europskog fonda za regionalni razvoj.

saznaj više